People are still astonished when they hear that our metal jewelry is also 3d printed. Just like the polyamide nylon material, the steel jewelry is printed from powder. There are various methods of metal printing available. When we first introduced steel jewelry in 2014 we were using the ‘binder jetting’ technology. With this method, the printer deposits small drops of glue between each layer of steel powder. After the print is complete, it goes through an infusion process that replaces the glue with bronze, creating a solid metal piece. In 2016 we switched to a more sophisticated way of metal printing called ‘laser metal fusion’ (or LMF) 3d printing. This metal printing technique builds objects layer by layer by fusing powered steel together.

Here you can see the laser metal fusion printer at work :

For each design we create a 3d computer file which is needed to manufacture the object. The metal printer has a ‘building platform’ of 10 cm maximum. So for each production, the operator will try to fit as many pieces on the platform as possible in order to achieve an optimal and efficient production run. For jewelry, sometimes we can fit 5 pieces when printing the larger items such as the necklace pendants or the bracelets or we can fit up to 50 pieces when we are printing the smaller items such as earrings or rings. Depending on the number and required density, the printer will take between 4 and 12 hours to print. When the jewelry is printed, it still is far from finished…

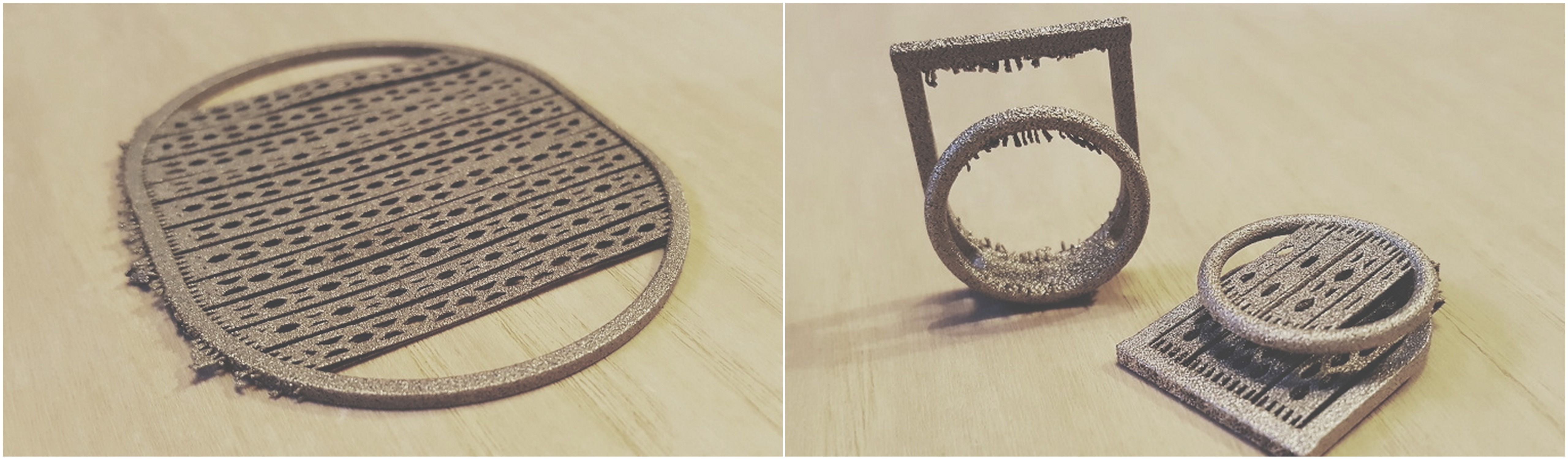

For each piece, regardless big or small, supports need to be printed as well so that the objects don’t collapse during the build process. Each of these supports has to be manually removed from the jewelry. After that, the rough ends smoothened out bit by bit with specialized equipment and finally the jewelry is tumbled for 20 hours in order to obtain a perfectly smooth surface.

For each piece, regardless big or small, supports need to be printed as well so that the objects don’t collapse during the build process. Each of these supports has to be manually removed from the jewelry. After that, the rough ends smoothened out bit by bit with specialized equipment and finally the jewelry is tumbled for 20 hours in order to obtain a perfectly smooth surface.

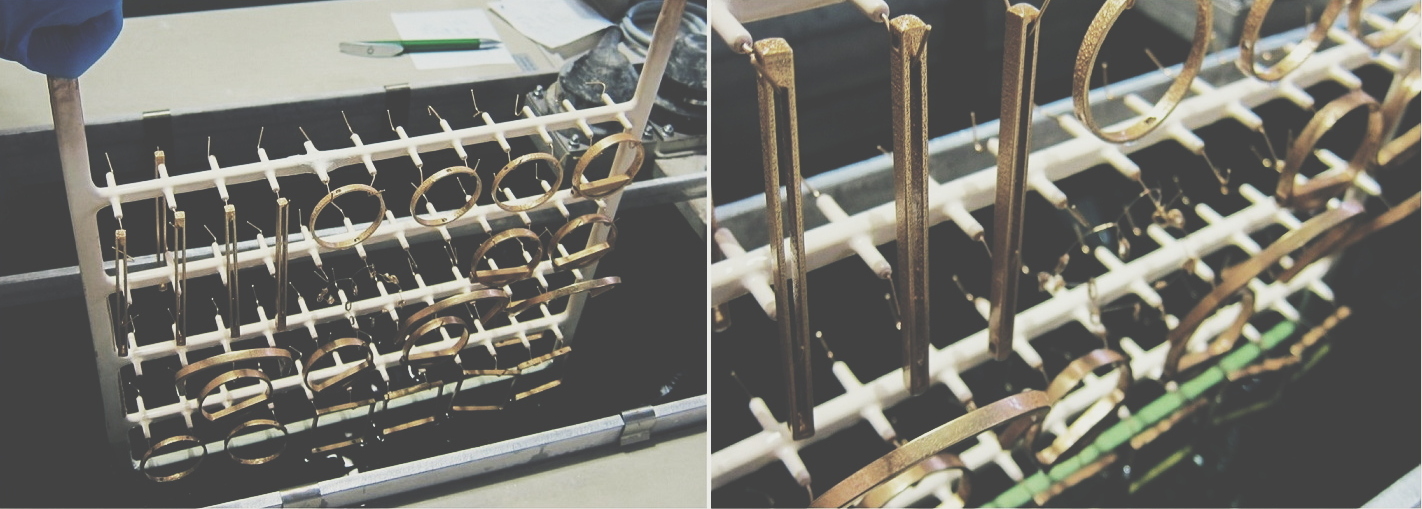

Now the jewelry is ready for plating… First, every piece is given a base layer and after that all jewelry is silver-plated. The gold layer goes on top of the silver. The silver pieces also receive a ‘nano protection’ layer to avoid oxidation.

Now the jewelry is ready for plating… First, every piece is given a base layer and after that all jewelry is silver-plated. The gold layer goes on top of the silver. The silver pieces also receive a ‘nano protection’ layer to avoid oxidation.

The production of 3d printed metal jewelry is quite a complex process but gives a unique result in surface finishing and allows for extraordinary geometric shapes. It’s an incredible technology ! We are curious to see how it is going to evolve and what other materials will be launched in the future…

The final result…

The final result…